Improving the quality of diagnostic imaging service through knowledge, education and Fully Engaged Hands-on Learning™.

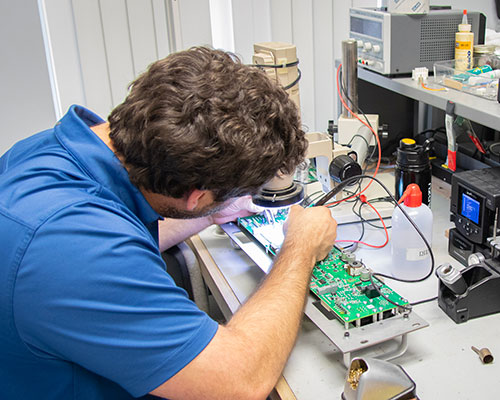

Fully Engaged Hands-on Learning™

Our Fully Engaged Hands-on Learning™ puts the student at the center of the training experience with practical hands-on instruction.

Why Choose RSTIState-of-the-art Facility

Our 40,000 square foot training facility features more than 50 equipment bays designed to simulate real-life healthcare environments.

See our Facility35+ Years of Training Experience

Since 1985, RSTI has provided the highest quality diagnostic imaging training to over 15,000 service professionals.

About Us

Parts, Equipment, Service & Support

With one of the largest inventories in the industry, we offer parts and equipment sourcing, extended services and 24/7/365 support.

Parts & Equipment

Earn Rewards with RSTI

The eXchange Loyalty Program rewards you with exclusive

discounts and benefits when you purchase parts, equipment

and training from RSTI.

You can earn:

- Free training credits and discounts

- Priority access to parts ID and tech support

- Save on inventory restock fees

- Engineer reassurance and intern access

- Extended warranties and core returns